Inspired by a Ugears Clock, I’ve decided to embark on creating a mechanical clock.

Gear Generator can simulate gears and let you create ‘child’ gears to parents and even has the gear-down ratio.

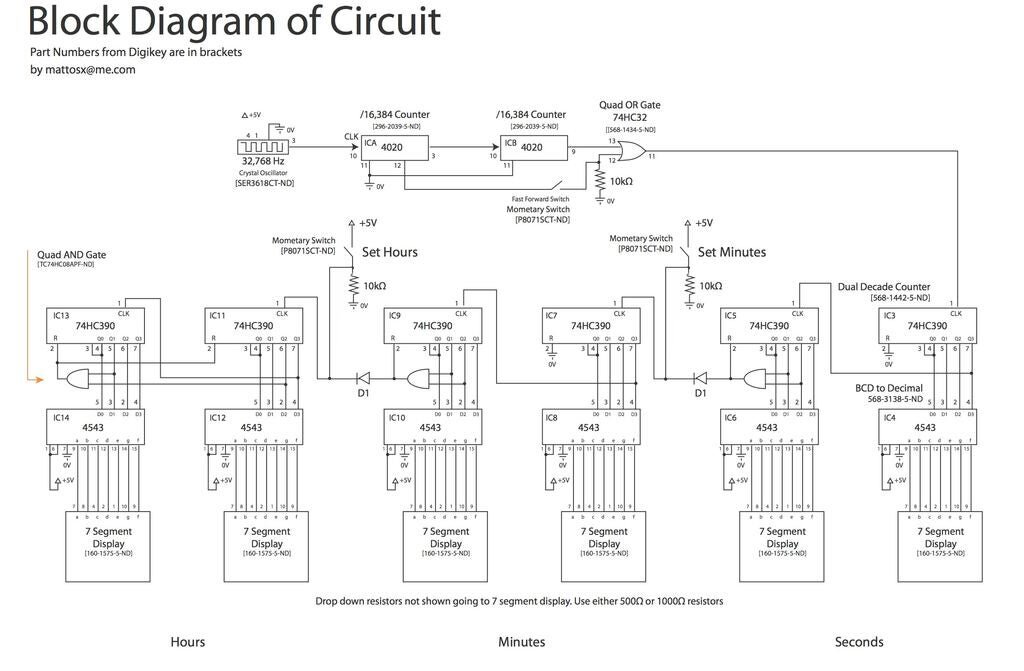

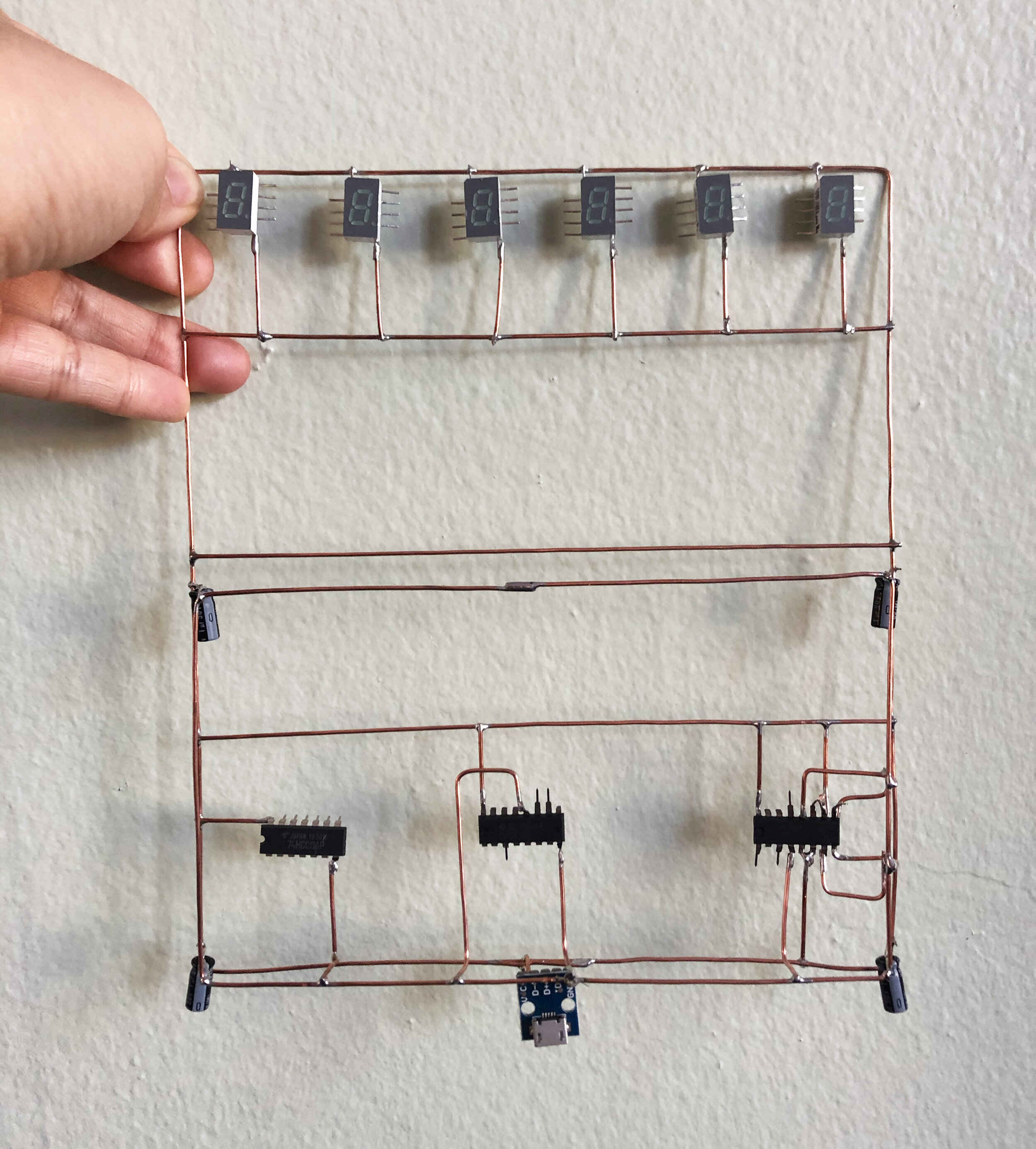

Schematics (as of Dec 3, 2019)

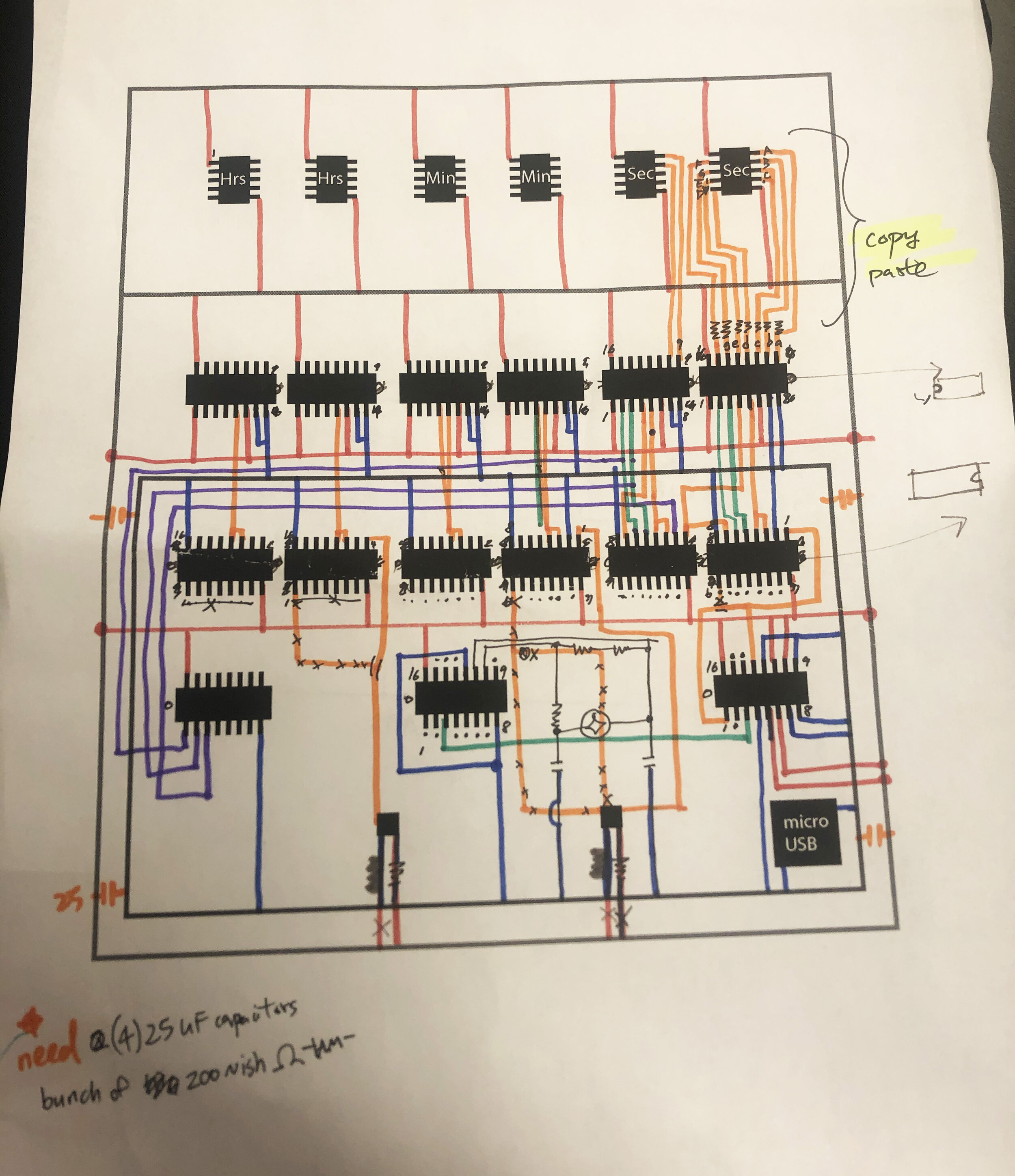

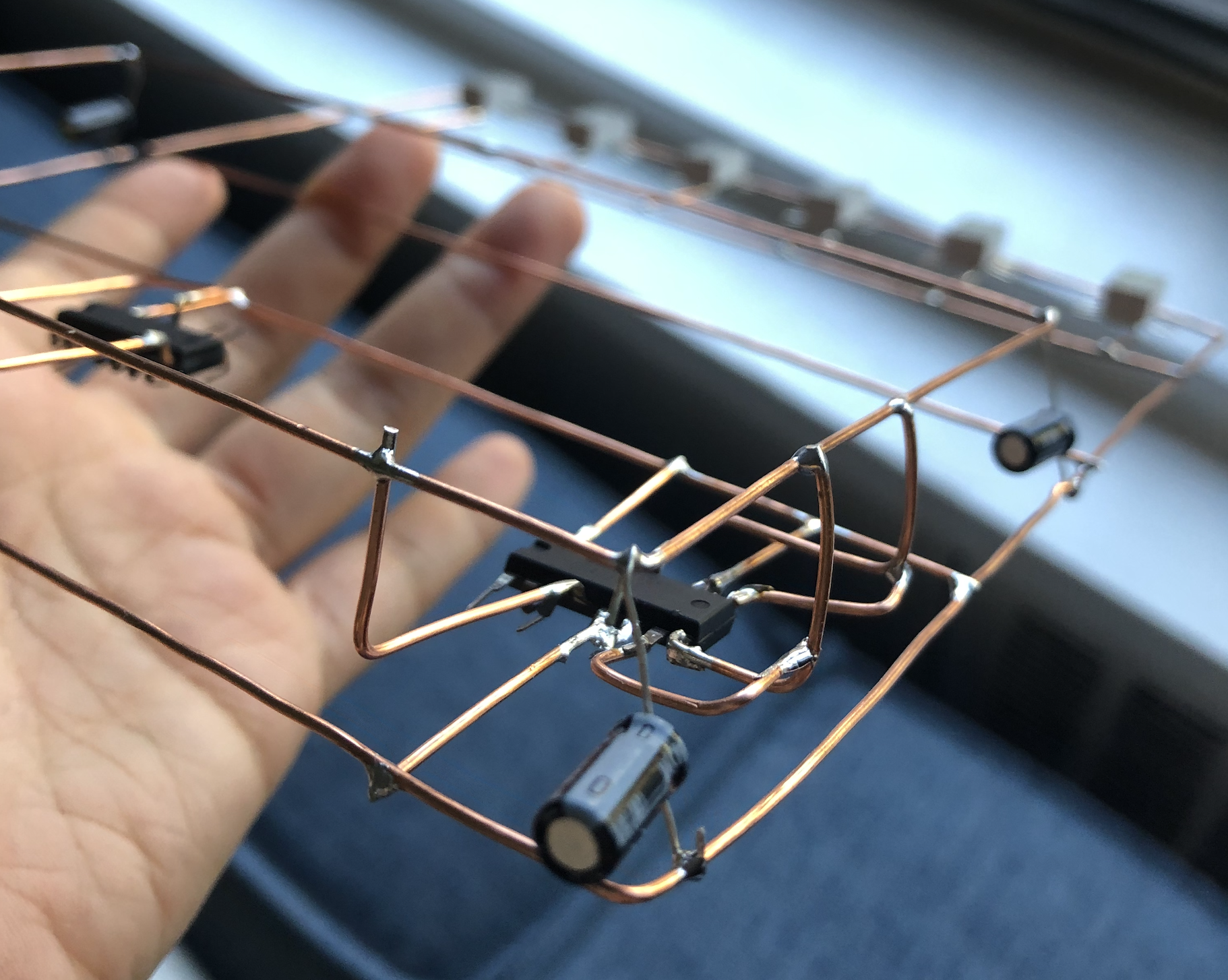

This is the approximation of the depth view. The gear columns will be made out of stacked acrylic pieces that are 4.5mm each, and thus is 45mm for the inside dimension. (approximate).

Here is the profile overview of the contraption and gear set. The colors note where the gears are in terms of the height (refer to the color chart above). The first gear (from the left) rotates once per minute, the big blue gear in the center marks the minutes, and the last gear on the right marks the hours.

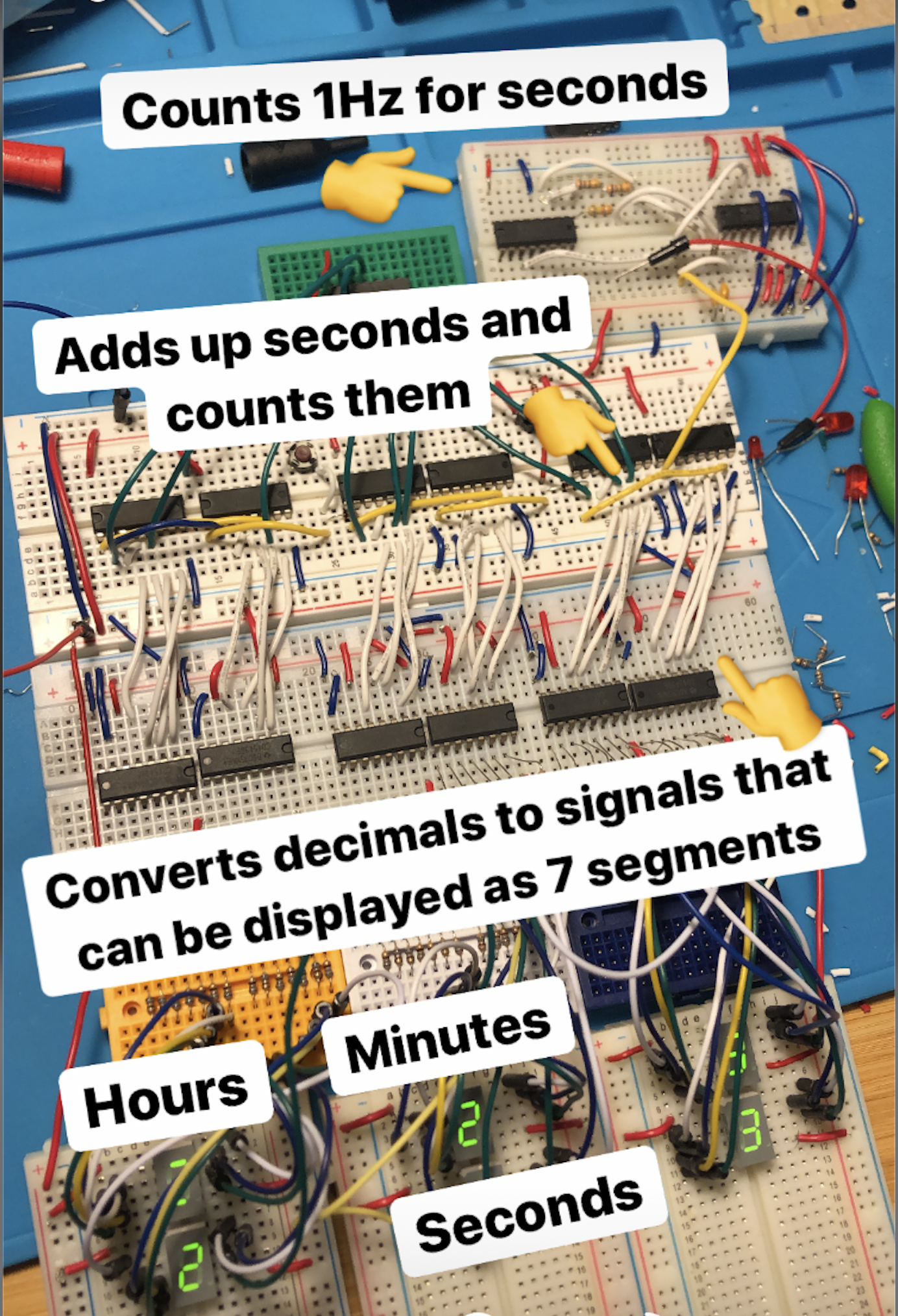

Process Documentation:

I cut a prototype with 3mm acrylic. Determined that I compensated too much for the laser kerf and the acrylic probably needs to be thicker. I was also using 5mm metal rods but this could also be acrylic to make everything more transparent. Also, the grey epoxy is a definite no. Also I thought I’d be able to put the motor in the back but this will make everything so much thicker.

As a solution for making the contraption thinner, I ordered worm gear parts. Need to redesign my box since the motor is now taking up horizontal space.

Also, I might be sticking to metal rods for the first gear in case the metal component can wear down the acrylic rod.